Eustis Estate

Eustis Estate

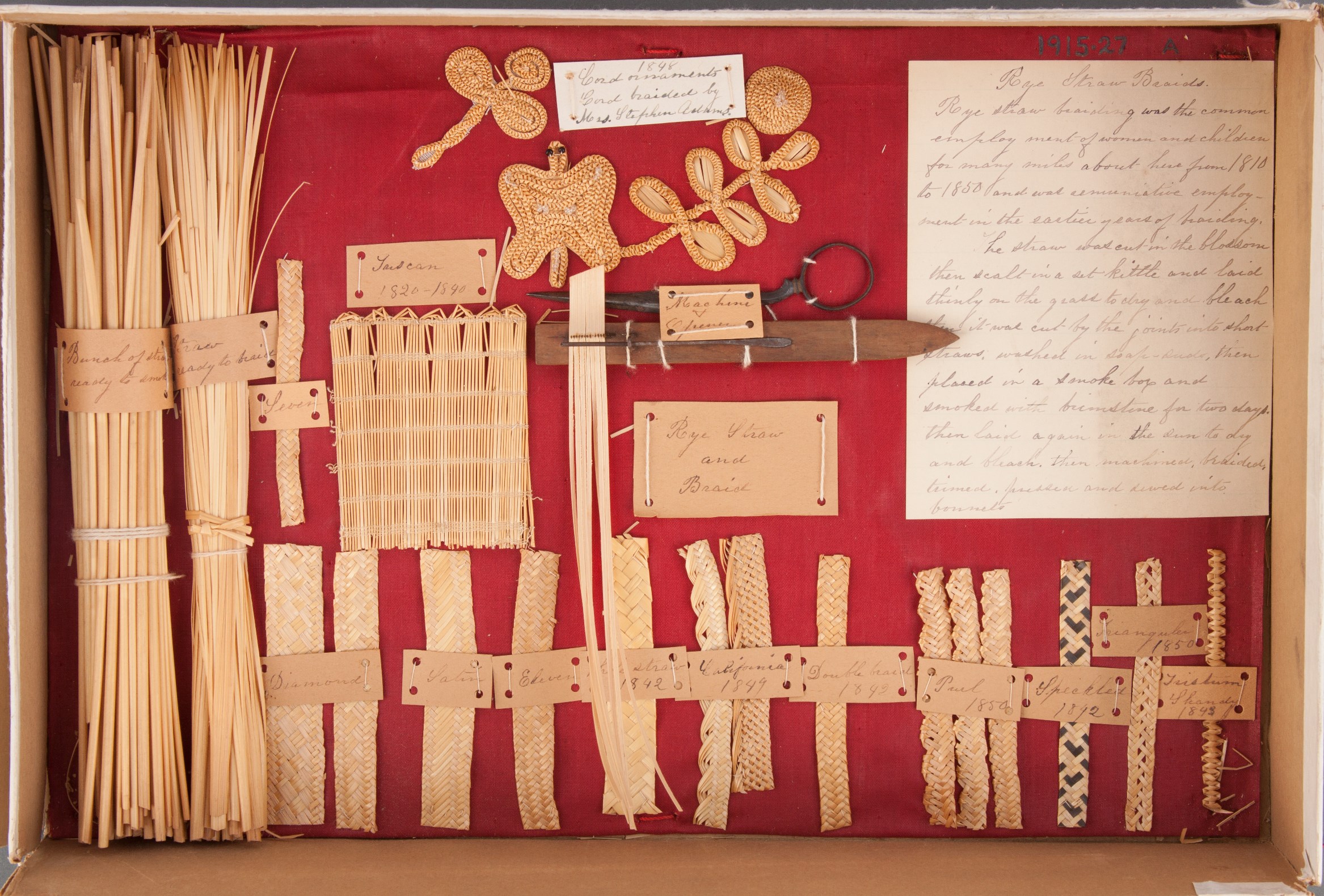

Straw Braiding

Julia A. Adams, who assembled this group of straw braiding samples, worked in a Medway, Massachusetts bonnet factory, most likely the Metcalf factory. Begun in 1842, the Metcalf factory was one of the largest employers in town and part of a regional economy that employed more women in the early to mid-nineteenth century in Massachusetts than textile or shoe production. Many authors over the years have attributed the origins of New England straw bonnet manufacturing to a single woman, Bestey Metcalf, sometimes misidentified as Hannah. The story revolves around an imported Italian “Leghorn” hat Betsey saw in a window but could not afford. Made with fine straw bleached almost white, these beautiful accessories were far beyond Betsey’s modest pocketbook, so the enterprising young woman decided to make her own bonnet with local rye straw. Numerous interviews, letters, and details about Betsey seem to confirm aspects of this story. Miss Metcalf appears to have taught herself to braid, and encouraged her friends as well. But whether rye straw hats developed from the nimble fingers of a single inventor is less important than the impact domestic bonnet production had on the regional economy.

Beginning in the 1820s and 1830s over forty-eight percent of women who worked were employed in the production of straw and palm-leaf hats. Straw braiding paid half as much as textile or shoe factory labor, but it remained a consistent source of income and independence for many women in New England throughout the nineteenth century. Workers picked up raw materials from their local dry good merchant and braided lengths of split rye straw at home. They were typically paid by the foot of completed braid returned to the merchant, who then sold it to specialist milliners for making up into hats. Quite often straw braiders worked for the same stores where they shopped for their families. Later in the 1850s the first “factories” concentrated that portion of straw hat production under one roof, but they still relied on rural outwork in the region for braid production. Only the largest factories were vertically integrated and could take rye straw from raw product to finished hat.